Plastic Molding Machine: A Complete Buyer’s Guide for 2025

Choosing the right plastic molding machine is not just about acquiring a piece of equipment—it’s about securing the backbone of your manufacturing process. From everyday consumer goods to specialized industrial components, modern production depends on molding accuracy, energy efficiency, and reliable output. This guide breaks down what a plastic molding machine really does, the technologies available, cost considerations, and why working with a trusted partner like Daoben Machinery can redefine your production performance.

What is a Plastic Molding Machine?

A plastic molding machine is designed to melt polymer material and inject it into a mold cavity to form a part. It repeats this cycle consistently, ensuring uniformity in shape, size, and surface quality. While terms like moulding machine, injection molding machine, or plastic machinery are often used interchangeably, the concept remains the same: controlled heating, injection, cooling, and ejection.

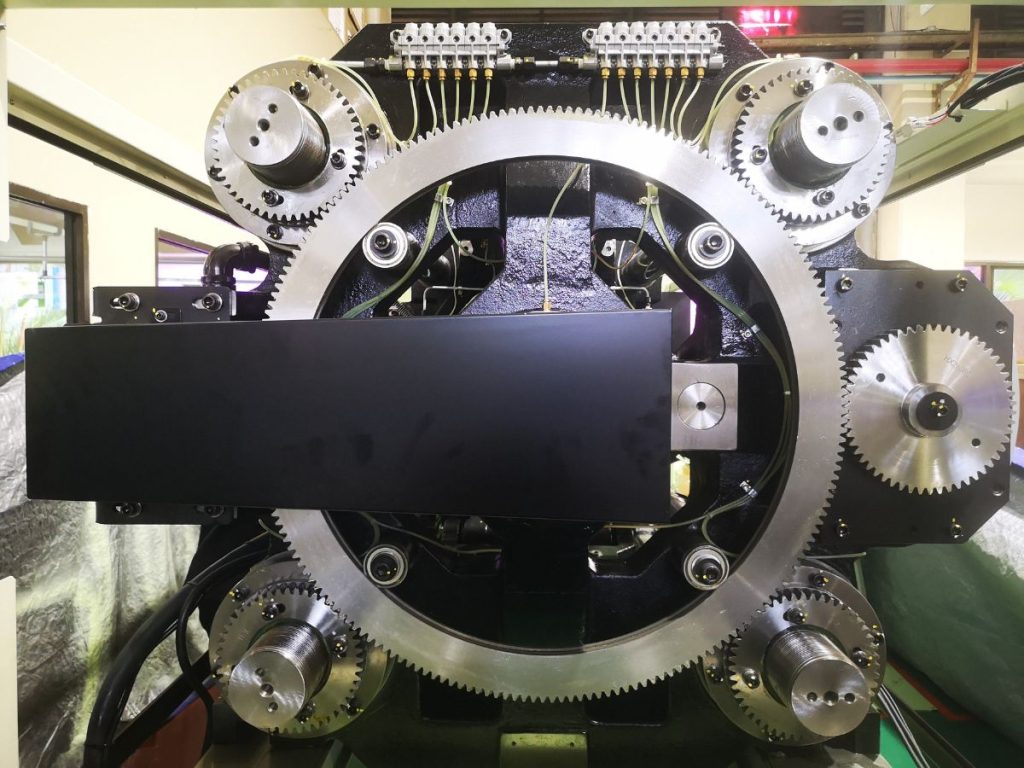

Core Components and Functions

Understanding the machine’s structure helps identify what matters during selection:

- Clamping Unit: Ensures mold halves remain tightly closed under tonnage during injection.

- Injection Unit: Melts, meters, and injects resin into the mold cavity.

- Drive System: Hydraulic, servo-hydraulic, or electric systems that power the machine.

- Control System: Software and HMI that regulate pressure, speed, and process parameters.

- Cooling System: Manages mold temperature for cycle consistency.

- Ejection Mechanism: Releases finished parts from the mold after solidification.

Types of Plastic Molding Machines

| Machine Type | Advantages | Applications |

|---|---|---|

| Hydraulic | High force, affordable, versatile | Large parts, automotive panels |

| Servo-Hydraulic | Energy-efficient, responsive | Packaging, consumer goods |

| All-Electric | Precision, cleanliness, low maintenance | Medical devices, electronics |

Each type fits different production goals. For example, servo-hydraulic systems balance energy savings with robust output, while all-electric machines dominate cleanroom environments.

Factors to Consider Before Buying

- Production Volume – High-volume runs benefit from faster, more automated systems.

- Part Size and Complexity – Larger molds demand higher tonnage and platen size.

- Material Properties – Engineering plastics require precise temperature and pressure control.

- Cycle Time Goals – The faster the cycle, the higher the daily output.

- Budget and Lifetime Cost – Balance upfront cost with energy, maintenance, and downtime savings.

Pricing Trends in 2025

Market reports indicate steady investment in automation, precision, and energy-efficient technology. Price varies by tonnage, drive type, and controller sophistication. While plastic injection molding machines with servo technology may cost more upfront, they deliver significant ROI through reduced power consumption and higher part consistency.

Price Drivers Include:

- Tonnage capacity

- Type of drive (hydraulic, servo, electric)

- Level of automation integration

- Mold compatibility and customization

- After-sales service and spare parts availability

Maintenance Practices to Extend Machine Life

- Daily: Inspect oil, heater bands, and barrel temperature.

- Weekly: Check filters, screws, and back pressure consistency.

- Monthly: Verify platen alignment and hydraulic oil condition.

- Annually: Conduct full calibration, safety checks, and control system updates.

Well-maintained moulding machines reduce defects, cut downtime, and protect mold investment.

Industry Applications

- Automotive: Dashboards, bumpers, interior trims

- Medical: Syringes, diagnostic devices, precision casings

- Packaging: Bottles, caps, containers

- Consumer Goods: Chairs, toys, household appliances

- Electronics: Connectors, enclosures, switches

Each sector emphasizes different qualities—automotive demands durability, medical insists on precision, and packaging prioritizes speed.

Why Work with Daoben Machinery

A critical factor in machine selection is the manufacturer’s reliability. Daoben Machinery has earned a reputation for producing stable, energy-efficient systems that align with global manufacturing demands. Businesses benefit from:

- Wide machine range from compact to high-tonnage models

- Integration-ready systems for robotics and QC automation

- Proven energy savings with servo-driven technology

- Reliable after-sales service and global spare parts support

- Flexible customization for industry-specific needs

The Bottom Line

A plastic molding machine is more than a piece of factory hardware—it’s the heartbeat of your production line. Choosing the right machine requires understanding your part requirements, cycle time goals, and resin characteristics.

To explore advanced solutions and machine configurations, consider visiting a trusted partner like Daoben Machinery. A seasoned molding machine manufacturer can guide you toward a system that improves efficiency, stabilizes production, and delivers a competitive edge.